What is Die casting

What is Die casing

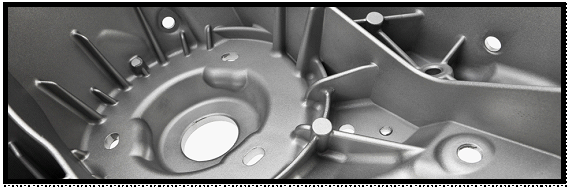

Die casting, or pressure casting, is a metal casting process, which is characterized by the use of mold cavity to melt the metal to exert high pressure. Molds are usually machined with higher strength alloys, and this process is somewhat similar to injection molding. Most die cast castings are iron free, such as zinc, copper, aluminum, magnesium, lead, tin and lead-tin alloys and their alloys. Depending on the type of die casting, a cold chamber die casting machine or a hot chamber die casting machine is required.

Casting equipment and molds are expensive, so die casting processes are generally only used to mass-produce large quantities of products. It is relatively easy to manufacture die-cast parts, which typically requires only four major steps, with a very low individual cost increment. Die casting is particularly suitable for the manufacture of large quantities of small and medium-sized castings, so die casting is the most widely used in a variety of casting processes. Compared with other casting technology, die-casting surface is more smooth, with a higher size consistency.

Step

The traditional die-casting process is mainly composed of four steps, or called high-pressure die-casting. These four steps include mold preparation, filling, injection and sanding, which are also the basis for a variety of improved die casting processes. In the preparation process need to spray the mold cavity on the lubricant, in addition to the lubricant can help control the temperature of the mold can also help cast off the mold. The mold can then be closed and the molten metal is injected into the mold with high pressure, which is in the range of about 10 to 175 MPa. When the molten metal is filled, the pressure will remain until the casting solidifies. And then put the push rod will launch all the castings, due to a mold may have multiple mold cavity, so each casting process may produce multiple castings. The process of sanding requires separation of the residue, including mold port, runner, gate and flash. This process is usually done by squeezing the casting with a special dressing die. Other sanding methods include sawing and grinding. If the gate is relatively fragile, you can directly hit the cast, this can save manpower. The extra mold port can be reused after melting. The usual yield is about 67%.

Advantages and disadvantages

The advantages of die casting include the casting with excellent dimensional accuracy. Usually this depends on the casting material, the typical value is the initial 2.5 cm size when the error is 0.1 mm, and the error is increased by 0.002 mm for each additional 1 cm. Compared to other casting processes, its cast surface is smooth, rounded radius of about 1-2.5 microns. Molds with a wall thickness of about 0.75 mm can be made with respect to sandbox or permanent die casting. It can directly cast the internal structure, such as silk sets, heating elements, high-strength bearing surface. Other advantages include the ability to reduce or avoid secondary machining, production speed, casting tensile strength of up to 415 MPa, can cast high-mobility metal.

The biggest drawback of die casting is the high cost. Casting equipment and molds, mold-related components are very expensive relative to other casting methods. So the manufacture of die-casting when the production of a large number of products is more economical. Other shortcomings include: This process is only applicable to the higher mobility of metal, and casting quality must be between 30 grams and 10 kg. In the usual die casting, the final cast of a batch of castings will always have porosity. So that no heat treatment or welding can be performed because the gas in the gap expands under heat, resulting in internal micro-defects and surface peeling.

XY-GLobal is the leading manufacturer that specializes in wide range of mechanical parts. Here is our website : www.xy-global.com .