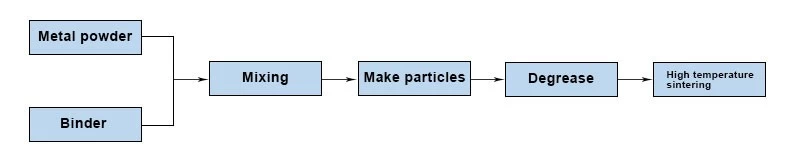

Metal powder injection molding process

Metal powder injection molding has higher requirements for raw material powder, including powder morphology, particle size, particle size composition, specific surface area, and bulk density. There are two main methods of raw material powder for metal powder injection molding: hydroxyl method and atomization method. Metal powder injection molding requires very fine raw material powder, so metal powder injection molding requires high.

Binder

Binders play a key role in metal injection molding technology. Only after adding a certain amount of binder, the powder has certain fluidity to be suitable for injection molding. After molding, the binder plays a role in maintaining the shape of the product.

The requirements of metal powder injection molding for the binder include: small contact angle with the powder, strong adhesion; no two-phase separation with the powder; certain strength after cooling; no cracking of the green body during degreasing, Serious defects such as bubbling; the viscosity of the pure adhesive at the injection temperature should be less than 0.1Pa·s.

Mixing

Mixing is the process of mixing raw powder and binder under a certain device and a certain temperature and fully and effectively stirring them to make them uniform and meet the requirements of injection. Because the nature of the feed determines the performance of the final product.

Therefore, the process step of mixing becomes very important, which will involve various factors such as the method and sequence of adding the binder and powder, the temperature of mixing, the characteristics of the mixing device, etc., and the final evaluation of the quality of the mixing process. An important indicator is the uniformity and consistency of the feed.Commonly used mixing devices include double screw extruder, type B impeller mixer, single screw extruder, plunger extruder, double planetary extruder, double cam mixer and so on.

Injection molding

In the powder injection molding process, injection molding is an important process that determines the production of qualified green bodies. The mixture is stirred and heated by the screw in the injection molding machine, and the plasticized mixture is injected into the mold cavity through the feeding system of the injection molding machine, and the pressure is maintained to compensate for the cooling shrinkage. After cooling and solidification, after the part has sufficient strength, open the mold and eject the part with a thimble to obtain a green body