Bakelite

Michelle

www.xy-global.com

2018-07-05 19:30:10

BakeliteIt is the first type of plastic to be put into industrial production. The chemical name of Bakelite is calledPhenolic plasticIt has high mechanical strength, good insulation, heat resistance and corrosion resistance, so it is often used in the manufacture of electrical materials, such as switches, lamp holders, earphones, telephone casings, instrument cases, etc. name.

Physical characteristics:

Phenolic plastic is a hard and brittle thermoset material.

The characteristics of bakelite are non-absorbent, non-conductive, high-temperature resistant, high-strength, and are often used in electrical appliances. Because of its high insulation and good plasticity like wood, it is called “bakelite”. Bakelite is a powdered phenolic resin, which is added to sawdust, asbestos or clay and mixed with a mold at a high temperature. The phenolic resin is the world's first synthetic resin.

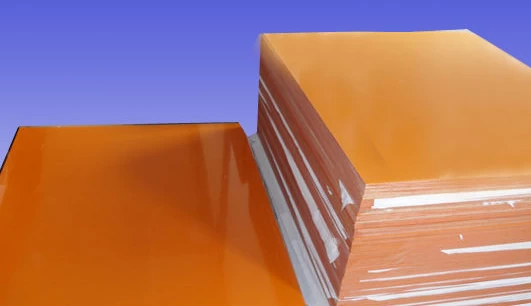

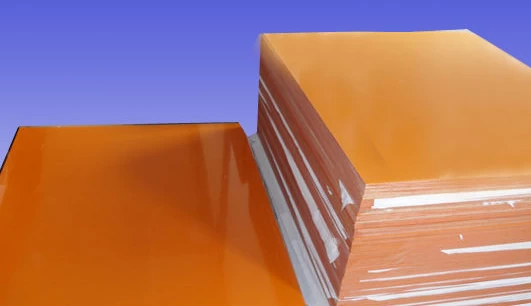

Phenolic plastic (bakelite): The surface is hard, brittle and fragile. It has a sound of wood and is mostly opaque dark (brown or black). It is not soft in hot water. It is an insulator whose main component is phenolic resin.

The characteristics of bakelite are non-absorbent, non-conductive, high-temperature resistant, high-strength, and are often used in electrical appliances. Because of its high insulation and good plasticity like wood, it is called “bakelite”. Bakelite is a powdered phenolic resin, which is added to sawdust, asbestos or clay and mixed with a mold at a high temperature. The phenolic resin is the world's first synthetic resin.

Phenolic plastic (bakelite): The surface is hard, brittle and fragile. It has a sound of wood and is mostly opaque dark (brown or black). It is not soft in hot water. It is an insulator whose main component is phenolic resin.

Molding performance

1. Good formability, but shrinkage and directionality are generally larger than aminoplasts and contain moisture volatiles. It should be preheated before molding, and should be vented during the molding process. If it is not preheated, the mold temperature and molding pressure should be increased.

2. The mold temperature has a great influence on the fluidity, and when it exceeds 160 degrees, the fluidity will drop rapidly.

3. The hardening speed is generally slower than that of aminoplasts, and the heat released during hardening is large. The internal temperature of large thick-walled plastic parts tends to be too high, and it is prone to hardening unevenness and overheating.

When the formaldehyde/phenol (molar ratio) is less than 1, the thermoplastic can be obtained.The product, called a thermoplastic phenolic resin, is a novolak type phenolic resin, which contains no further polycondensation groups, is added with a curing agent and heated to cure. For example, hexamethylenetetramine is used as a curing agent, and the curing temperature is 150 ° C. The molding powder mixed with filler is commonly known as bakelite powder. When the formaldehyde/phenol (molar ratio) is greater than 1, a base-stage resin, that is, a thermosetting phenolic resin, which is soluble in an organic solvent and contains a methylol group capable of further polycondensation, is not required under base catalysis. Adding a curing agent can cure: the reaction is heated to obtain a B-stage resin, also known as a semi-dissolved phenolic resin, which is insoluble and infutable but swellable and soft. Further reaction results in an insoluble and infusible bulk structure, a C-stage resin, also referred to as an insoluble phenolic resin. The long-term storage of the stage A resin also cures itself.

2. The mold temperature has a great influence on the fluidity, and when it exceeds 160 degrees, the fluidity will drop rapidly.

3. The hardening speed is generally slower than that of aminoplasts, and the heat released during hardening is large. The internal temperature of large thick-walled plastic parts tends to be too high, and it is prone to hardening unevenness and overheating.

When the formaldehyde/phenol (molar ratio) is less than 1, the thermoplastic can be obtained.The product, called a thermoplastic phenolic resin, is a novolak type phenolic resin, which contains no further polycondensation groups, is added with a curing agent and heated to cure. For example, hexamethylenetetramine is used as a curing agent, and the curing temperature is 150 ° C. The molding powder mixed with filler is commonly known as bakelite powder. When the formaldehyde/phenol (molar ratio) is greater than 1, a base-stage resin, that is, a thermosetting phenolic resin, which is soluble in an organic solvent and contains a methylol group capable of further polycondensation, is not required under base catalysis. Adding a curing agent can cure: the reaction is heated to obtain a B-stage resin, also known as a semi-dissolved phenolic resin, which is insoluble and infutable but swellable and soft. Further reaction results in an insoluble and infusible bulk structure, a C-stage resin, also referred to as an insoluble phenolic resin. The long-term storage of the stage A resin also cures itself.

The cured form of the thermosetting phenolic resin is classified into two types: room temperature curing and heat curing. At room temperature curing, a non-toxic normal temperature curing agent NL can be used, and benzenesulfonyl chloride or petroleum sulfonic acid can also be used, but the latter two materials are more toxic and irritating.

Disadvantage

The disadvantage of phenolic resin is that it has poor mechanical properties and is not resistant to oil and chemical corrosion. In order to overcome the above defects, phenolic resin has been modified, and different fillers are added to the phenolic resin to obtain modified phenolic plastics with different functions. If asbestos and mica are added to the ingredients, it can increase its acid resistance, alkali resistance and wear resistance. It can be used as a material for chemical equipment and accessories for motors and automobiles. Adding glass fiber can increase hardness and can be used as machine parts. After being modified with nitrile rubber, the oil resistance and impact strength are greatly improved; when modified with polyvinyl chloride, the mechanical strength and acid resistance can be improved.

Electric wood products

Bakelite has been widely used in many places in our lives, such as: bakelite sockets, bakelite switches, bakelite handles, bakelite cucurbits, bakelite records, bakelite handles, handles, handles, handles, tissue boxes, Kitchen stove table, bakelite tea tray, billiard ball, etc.

XY-Global It is a value-oriented supplier and medium-sized company with a variety of small plastic and metal parts. We understand that each part is a key part. Our Quality Our team will ensure that your work is completed in a timely manner to meet your needs and tailored to your specifications. We invite you to learn more about our abilities.

This is our website: Www.xy-global.com

This is our website: Www.xy-global.com