Special Sand Casting Process

naky

www.diecastingpartsupplier.com

2015-08-06 10:47:08

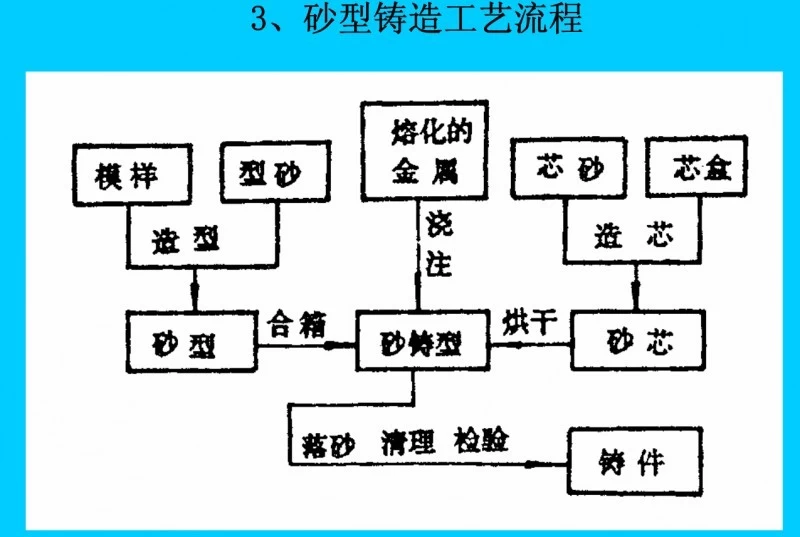

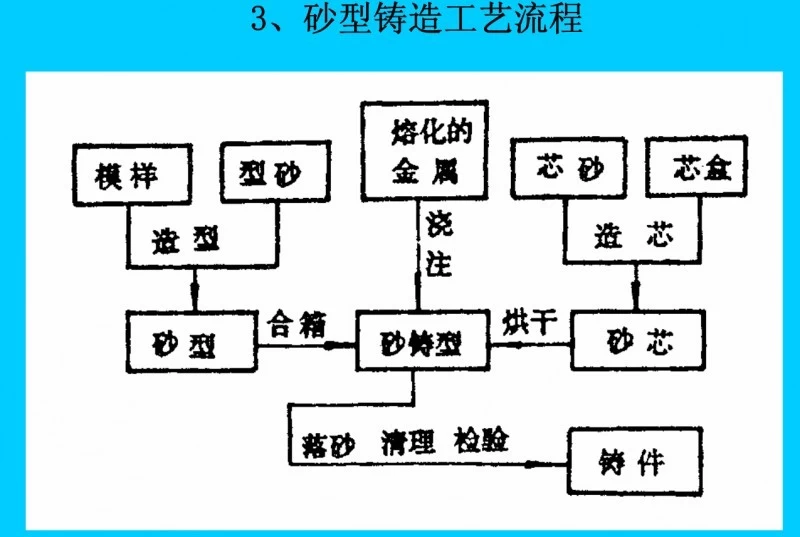

Sand casting is the most popular and easiest type of casting has been extended by several centuries. Sand casting is used to manufacture large components, such as gray iron, ductile iron, stainless steel and other steel and other types of sand casting processes. The main steps include painting, mold, core, shape, melting and casting, cleaning and so on.

1,Sand casting process of drawing:

The traditional method is to obtain casting drawings and drawings sent to the foundry. This process can be completed in the offer. Today, more and more customers and foundry manufacturers to use computer-aided design in place.

The traditional method is to obtain casting drawings and drawings sent to the foundry. This process can be completed in the offer. Today, more and more customers and foundry manufacturers to use computer-aided design in place.

2, sand casting process Mold:

In sand casting mold is to use wood or other metal materials. In this process, we asked our engineers, the die size is slightly larger than the finished product, which is called the difference between the shrinking margin. Wherein the object is the effect of the molten metal to the mold and to ensure that the molten metal solidification contraction, thereby preventing the cavity during casting.

In sand casting mold is to use wood or other metal materials. In this process, we asked our engineers, the die size is slightly larger than the finished product, which is called the difference between the shrinking margin. Wherein the object is the effect of the molten metal to the mold and to ensure that the molten metal solidification contraction, thereby preventing the cavity during casting.

3, sand casting process of the system core:

Made only by the resin sand core placed in a mold to form the casting interior surface. Therefore, the gap between the core and the mold eventually become casting.

Made only by the resin sand core placed in a mold to form the casting interior surface. Therefore, the gap between the core and the mold eventually become casting.

4, sand casting process of forming:

In the melting molding process you need to prepare a pair of molds. Generally involves molding mold support frame, pulled to separate the mold during casting, in previously placed in a mold and then melted core mold is closed port.

In the melting molding process you need to prepare a pair of molds. Generally involves molding mold support frame, pulled to separate the mold during casting, in previously placed in a mold and then melted core mold is closed port.

5, clean sand casting process of

The purpose of cleaning is to remove the sand, polish and excess metal casting. Welding, grit removal to improve the surface appearance Casting

Burned and scale removal of sand to improve the surface appearance of the casting. Excess metal and other riser is clear. Welding grinding and other steps closer again. Finally, check the defect and overall quality.

The purpose of cleaning is to remove the sand, polish and excess metal casting. Welding, grit removal to improve the surface appearance Casting

Burned and scale removal of sand to improve the surface appearance of the casting. Excess metal and other riser is clear. Welding grinding and other steps closer again. Finally, check the defect and overall quality.