How to control the quality of die casting aluminum?

From a professional point of view, I will tell you how to control the quality of die-casting aluminum, which can be summarized into the following two points:

1. Control raw materials

In order to ensure the quality of die-casting and improve the qualified rate of products, the quality should be strictly controlled when selecting raw materials. Usually, the chemical composition of the main elements of the alloy is determined by sampling inspection of each incoming material, and then the die-casting, processing, surface treatment and The influence of other subsequent processes, the chemical composition of aluminum, zinc, magnesium, copper, iron and other chemical components is strictly controlled.

2. Mold quality control

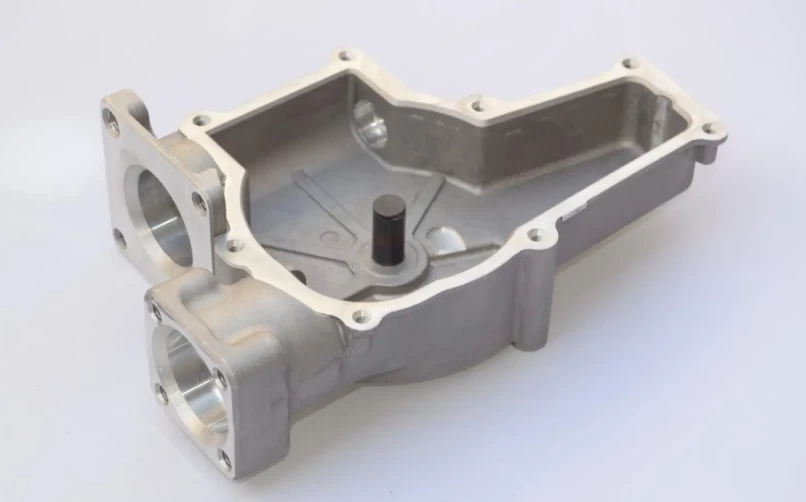

The quality of aluminum die castings is directly related to the structural design of the mold. For example, the inner gate should ensure that the alloy smelting has appropriate flow, flow and pressure; the design of the overflow tank should ensure that the metal can fill the mold cavity, thereby reducing die casting defects, such as casting Defects, loosening, shrinkage holes, etc.; the design of the exhaust tank should make the exhaust smooth. Only by designing the mold structure will it not affect the quality and production efficiency of aluminum die castings.

The quality of aluminum die castings must pay attention to raw materials and molds. Only by controlling the quality from these aspects can we obtain high-quality die castings.

As a modern manufacturer of precision mechanical parts, xy-global takes die-casting and CNC processing as its core processes, has physical factories, testing equipment, and integrates supporting manufacturing resources such as rapid prototyping, molds, and post-processing to provide customers with rapid proofing, Small and medium-sized batch production and trial assembly, truly a one-stop service that saves effort and effort; the company has Taiwan imported computer gongs, milling machines, lathes, grinders and other precision machining equipment, as well as a technical team with non-standard production experience.