How does a water jet cutter work

How does a water jet cutter work

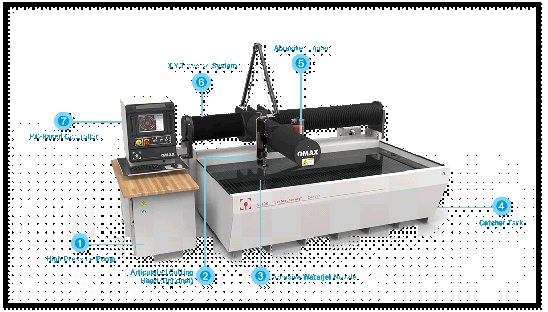

A water jet cutter, also known as a water jet or waterjet, is an industrial tool capable of cutting a wide variety of materials using a very high-pressure jet of water, or a mixture of water and an abrasive substance. The term abrasive jet refers specifically to the use of a mixture of water and abrasive to cut hard materials such as metal or granite, while the terms pure waterjet and water-only cutting refer to waterjet cutting without the use of added abrasives, often used for softer materials such as wood or rubber.

Waterjet cutting is often used during fabrication of machine parts. It is the preferred method when the materials being cut are sensitive to the high temperatures generated by other methods. Waterjet cutting is used in various industries, including mining and aerospace, for cutting, shaping, and reaming.

Benefit of waterjet

1. Cuts virtually any material。

2. Smooth cutting, no rough burrs.

3. Dosen’t release heat (or a small amount of heat).

4. Dosen’t release gas

5. Nozzle can handle different types of materials and shapes

Process of waterjet

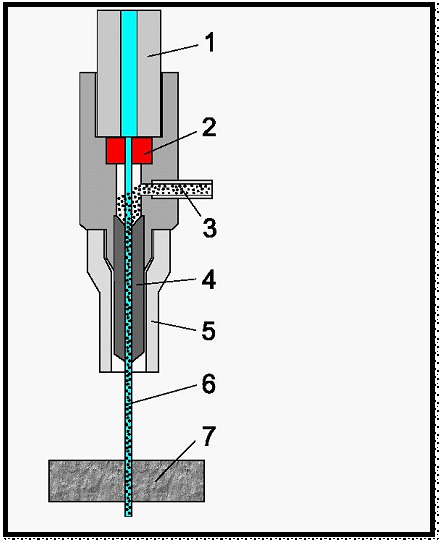

All waterjets follow the same principle of using high pressure water focused into a beam by a nozzle. Most machines accomplish this by first running the water through a high pressure pump. There are two types of pumps used to create this high pressure; an intensifier pump and a direct drive or crankshaft pump. A direct drive pump works much like a car engine, forcing water through high pressure tubing using plungers attached to a crankshaft. An intensifier pump creates pressure by using hydraulic oil to move a piston forcing the water through a tiny hole. The water then travels along the high pressure tubing to the nozzle of the waterjet. In the nozzle, the water is focused into a thin beam by a jewel orifice. This beam of water is ejected from the nozzle, cutting through the material by spraying it with the jet of high-speed water. The process is the same for abrasive waterjets until the water reaches the nozzle. Here abrasives such as garnet and aluminium oxide, are fed into the nozzle via an abrasive inlet. The abrasive then mixes with the water in a mixing tube and is forced out the end at high pressure.

XY-Global serves its world class-customers by manufacturing die casting parts, CNC machining parts, and injection molding. We tackle complex manufacturing problem for our customers, which include Tier 1, Tier 2 and OEM clients in telecommunications, 3D printer and other industries.

If you have any project, please try us. We also offer design assistance. Here is our webstie : www.xy-global.com .