Precision die casting process

Nancy

www.diecastingpartsupplier.com

2014-08-27 18:17:23

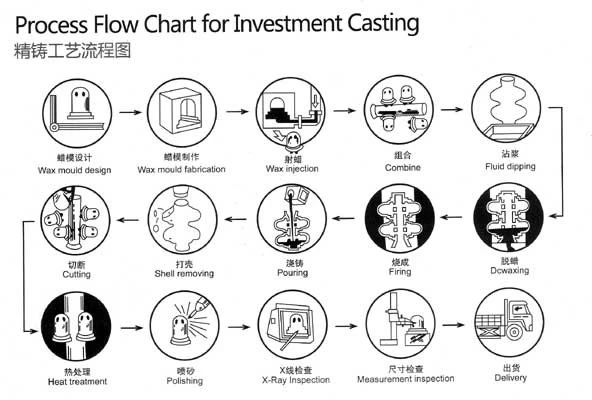

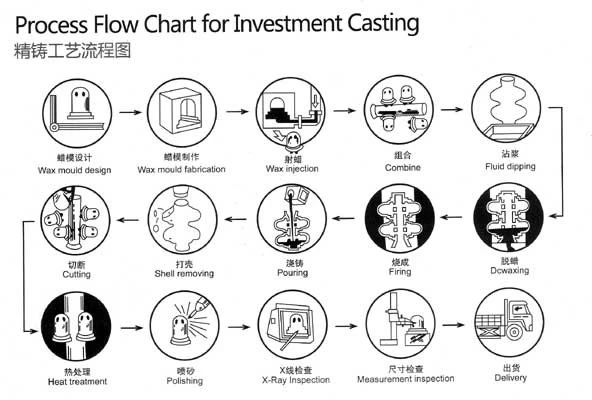

Mold Design ----- abrasive manufacturing ---- pressure repair wax ----- ----- ------- Shell group tree (James pulp) ----- dewaxing ---- shell firing ------ resistance analysis --- heat pouring ---- cleanup ----- ----- ------- machined product storage.

Details are: pressure wax (wax injection molding) --- repair Wax ---- Wax seized ---- Group Tree (December module tree) --- Shell (first dip syrup, pour sand, then dip pulp, and finally dried formwork) --- dewaxing (steam dewaxing) ------- formwork roasting - resistance analysis - casting (pouring molten steel in the mold shell) ---- shock shelling --- casting and casting rods cut separation ---- mill gate --- early detection (blank check) --- shot blasting machine processing ----- ----- finished polishing --- check --- storage

Overall casting production process can be divided roughly pressed wax, shell, casting, post-processing, testing pressure waxes include (pressure wax, repair wax, group tree) --- Pressure wax wax machine produced by press molding wax repair --- wax mold for December correction group tree --- will be set tree wax mold include shell (hanging sand, hanging pulp, dried), including post-treatment (correction, shot blasting, sand blasting, pickling,) cast includes (roasting, also called the fight resistance spectrum analysis, casting, shell shock, cut gate, mill gate) after treatment include (sand blasting, shot blasting, correction, pickling) tests include (wax inspection, initial inspection, in-process inspection, product inspection)

Details are: pressure wax (wax injection molding) --- repair Wax ---- Wax seized ---- Group Tree (December module tree) --- Shell (first dip syrup, pour sand, then dip pulp, and finally dried formwork) --- dewaxing (steam dewaxing) ------- formwork roasting - resistance analysis - casting (pouring molten steel in the mold shell) ---- shock shelling --- casting and casting rods cut separation ---- mill gate --- early detection (blank check) --- shot blasting machine processing ----- ----- finished polishing --- check --- storage

Overall casting production process can be divided roughly pressed wax, shell, casting, post-processing, testing pressure waxes include (pressure wax, repair wax, group tree) --- Pressure wax wax machine produced by press molding wax repair --- wax mold for December correction group tree --- will be set tree wax mold include shell (hanging sand, hanging pulp, dried), including post-treatment (correction, shot blasting, sand blasting, pickling,) cast includes (roasting, also called the fight resistance spectrum analysis, casting, shell shock, cut gate, mill gate) after treatment include (sand blasting, shot blasting, correction, pickling) tests include (wax inspection, initial inspection, in-process inspection, product inspection)