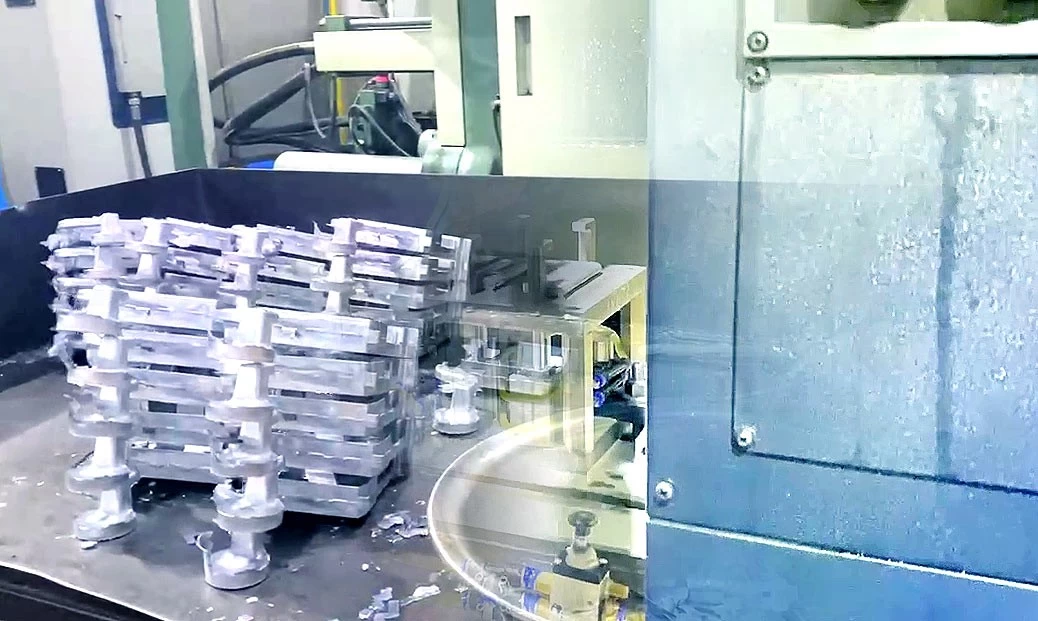

Processing requirements of alloy die casting

Designed for alloy die casting. The operating temperature can be as high as 350°C, which can meet the temperature requirements of die-casting of aluminum alloys, magnesium alloys, zinc alloys and other alloys.

The alloy die-casting process has relatively high requirements on the temperature control of the mold. The temperature of the mold is a key factor in the heat dissipation of the metal solution, the filling of the mold and the solidification of the casting. In many cases abnormal mold temperatures can cause casting defects.

Alloy die casting generally has a higher temperature. In order to meet the required mold temperature, the traditional process usually uses petroleum air gun or plug-in heating tube to heat the mold, and the mold temperature is not uniform and the effect is not good. We all know that in the die casting process, the alloy solution enters the mold cavity through pressure, and the heat loss solidifies and forms, and the die casting is obtained. The temperature control of the mold plays a key role in die casting production. If the heat loss is too fast, the die-casting will produce cold lines, the heat dissipation will be slow, the die-casting molding time will be increased, and the productivity will be reduced. Therefore, mold temperature control means that the mold is heated and maintained at a certain working temperature to ensure stable quality of castings, shorten the compression cycle, and prolong the service life of the mold.

The ideal method is to heat the mold with a die casting mold. Using the high heat transfer and fluidity of the heat transfer oil, the mold is indirectly heated by the heated heat transfer oil to make the mold reach the required temperature.