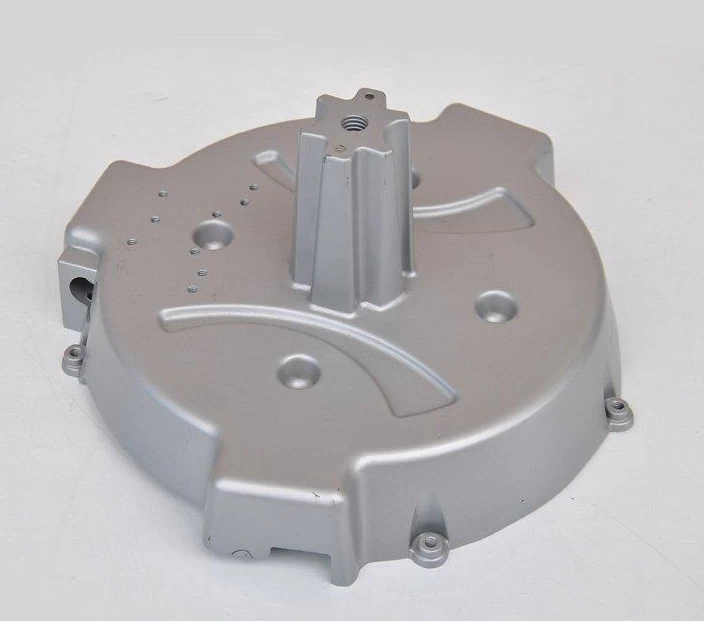

Porosity inspection of castings

With the rapid development of the automobile industry and the obvious increase in demand for automobile lightweight, aluminum, magnesium and other alloy die-casting parts, the lightweight requirements of parts have put forward higher requirements for alloy material performance, product structure, process design and control

.

Automobile die castings have more and more stringent requirements for die castings. The porosity requirements of die castings are generally 5%≤10%, and the requirements for some parts are even 3%. According to the detection method and location of the die-casting defect, in the die-casting machine model selection, mold design and process design, it can be optimized with the aid of computer simulation analysis.

There are pores, shrinkage and slag hole defects in die castings, and the reasons for the defects are different. In order to identify the type of defect and analyze the cause of the defect, it is particularly important to identify the type of defect and analyze its cause. The tools and methods for detecting parts will affect subsequent judgments. The following discusses how to solve the hole problem of aluminum and magnesium alloy die-casting.

In the pore detection of die-cast aluminum castings, the following positions should be considered:

(1) Location of large stress in finite element analysis;

(2) The position of the gas coil in the part simulation analysis;

(3) Key components (such as sealing surface, etc.).

Die castings can be inspected by X-rays, and further inspections can be made after defects are found. In process control, according to ASTME 505 secondary control, key components should be controlled by ASTME505 primary control. The stomata are generally smooth, round or oval, sometimes isolated, and sometimes clustered together. The shape of shrinkage cavities and shrinkage pores are irregular, and the surface color is dark and not smooth. Under the microscope and electron microscope, it can be found that the defect site has a dendritic structure.

Sometimes the pores and shrinkage holes exist at the same defect location at the same time, which requires careful observation. The design of die-casting parts is an important part of the die-casting production process. The following issues should be considered when designing: selection of mold parting surface, gate opening, ejector position selection, casting shrinkage, guarantee of casting dimensional accuracy, prevention of casting internal defects, relevant requirements for casting holes, and deformation requirements And the size of the processing margin, etc.

Secondly, the design principles of die casting are:

1. The correct choice of die-casting materials,

2. Reasonably determine the dimensional accuracy of die castings;

3. Make the wall thickness distribution as even as possible;

4. Increase the craft fillet at each corner to avoid acute corners.

XY-GLOBAL?is qualified supplier of HP and Flextronics Israel for aluminum die casting over 8 years. We believe that we can support you fully. Pls kindly send your 2D and 3D drawing to us for checking the quality of our factory. Of course, we will sign the confidential document with you to protect you.Pls kindly know more from http://www.diecastingpartsupplier.com