MIM process manufacturing

LanKai

Www.xy-global.com

2018-06-14 09:30:23

MIM process manufacturing

MIM (full name: metal injection molding) is a new kind of powder metallurgy technology, which is similar to the Net Shape Forming technology appearing in the plastic injection molding industry. As we know, plastic injection molding technology produces a variety of complex shapes at a low price. However, the strength of plastic products is not high. To improve its performance. The solution is to add metal or ceramic powders to the plastic to achieve high strength and good wear resistance. In recent years, this solution has been widely used.

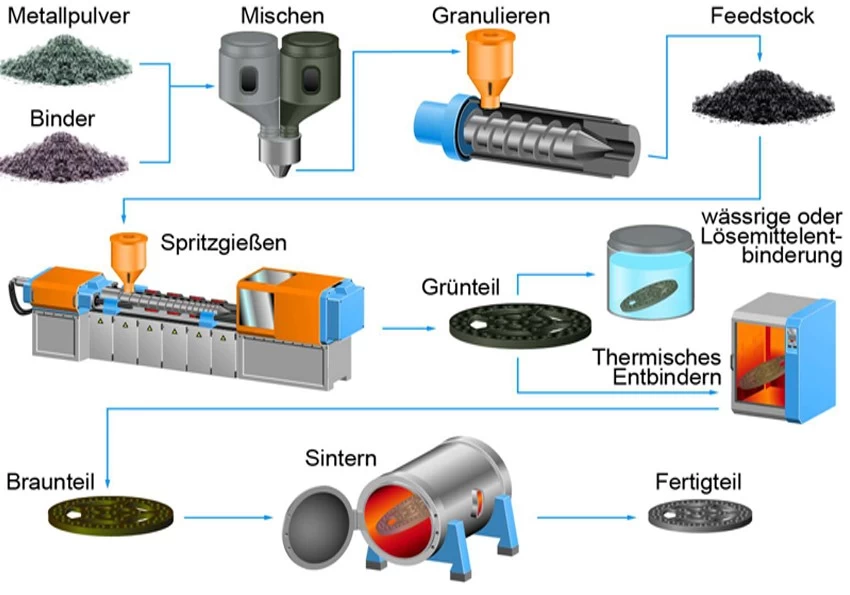

MIM process:

The binder is the core of the MIM technology. In the MIM, the binder has two basic functions of enhanced fluidity for injection molding and maintenance of briquette shape. In addition, it should have easy removal, no pollution, and no toxicity. Due to the characteristics of reasonable cost, a variety of adhesives have emerged. In recent years, the adhesive has been gradually selected from experience alone, and the adhesive has been specifically designed according to the requirements of the degreasing method and the function of the adhesive.

MIM process:

Note: Binder is most important in the MIM Process

The binder is the core of the MIM technology. In the MIM, the binder has two basic functions of enhanced fluidity for injection molding and maintenance of briquette shape. In addition, it should have easy removal, no pollution, and no toxicity. Due to the characteristics of reasonable cost, a variety of adhesives have emerged. In recent years, the adhesive has been gradually selected from experience alone, and the adhesive has been specifically designed according to the requirements of the degreasing method and the function of the adhesive.

XY-Globsl has more than 10years of experience in CNC machining of parts and die-cast parts. The main production of custom metal parts, injection molded parts......

You can find more information at our website: http://www.xy-global.com

Contact us

Email: sales870@xy-global.com

Skype:sales850@xy-global.com