How to ensure the accuracy of die casting aluminum alloy

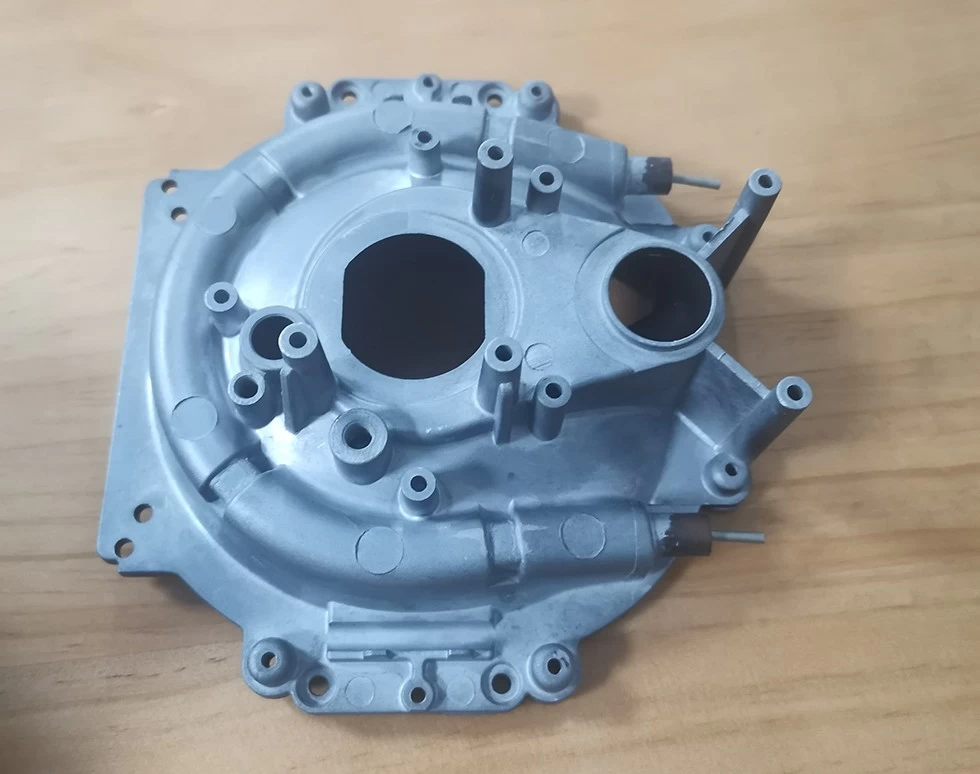

It is understood that two rubber sealing gasket for the production of die-cast molds. Two segments open for mold production for mold production for the production of individual components, and therefore assembled in combination, an excellent processing technology, easy to test the die-cast mold. The material of the die casting mold of the single cavity is CRLZ and the joint plate is 45 steel. In the processing process of die-casting fusion, in addition to strictly in accordance with the die-casting of the drawing processing reasons, to guarantee the specification of the cavity, the following points are the key to ensuring the accuracy of die-cast die-cast: die-cast aluminum alloy

1. Processing of the groove flow: In the past, the quality of processing of the groove of the die-casting mold flow of the oil flow has not been sufficient attention. The flow groove is often processed on the distance of the cavity or the specification is not easy to control, which makes it difficult to cut the product and the product is not beautiful. Two seal of the open oil die casting to solve these problems has been made to improve, the flow of the Glove Groove End triangle specifications and the specifications of the product diameter (zero zero), using the division of the upper and lower mold here constitute A sharp blade, with the oil holding mold, the residual flash has been shot down, the clipping process is simplified and improves the appearance of the quality of the product.

2. Collaborative processing of the Upper Dice and the Upper Core 1: the cooperation of the Upper Dice and the Upper Stadium Core 1 is conical cooperation. The previous search and correspondence method is selected and the Touch rate is required to reach more than 80%. This traditional method of processing is not only difficult, but also consumes a lot of hours of man. It is still difficult to reach the goal of no flying board, so there is no steering wheel of the product here. And the production process of die-casting molds has improved.

3, on the core of mold 1 and 2 on the pressure of the mold core: on the core of mold 1 and 2 on the pressure of the mold core it is to guarantee the specification of the oil holding lip and the precision of the key. The flying edge of the secondary lip of the die casting mold of the three open oil gaskets has a great influence on the quality of the appearance of the secondary lip.

4. Connection between each mold for die-casting of the cavity: the connection between each single die-cast mold cavity and the junction plate must have a certain amount of floating, to ensure that the die-cast molding mold opening and closing closing, accurate alignment. Generally, the gap between single mode and the coupling plate is controlled at 0.50 to 1. 0 RNM.