Good zinc alloy die casting manufacturer characteristics

With the development of die casting industry, different planning of zinc alloy die casting plants have appeared in various cities, and the competition is also very fierce. There are many factors affecting the price of zinc alloy die casting, such as equipment difference, enterprise planning, product quality, pre-sale and after-sales service, etc. For high quality zinc alloy die casting plant, how many of the following .

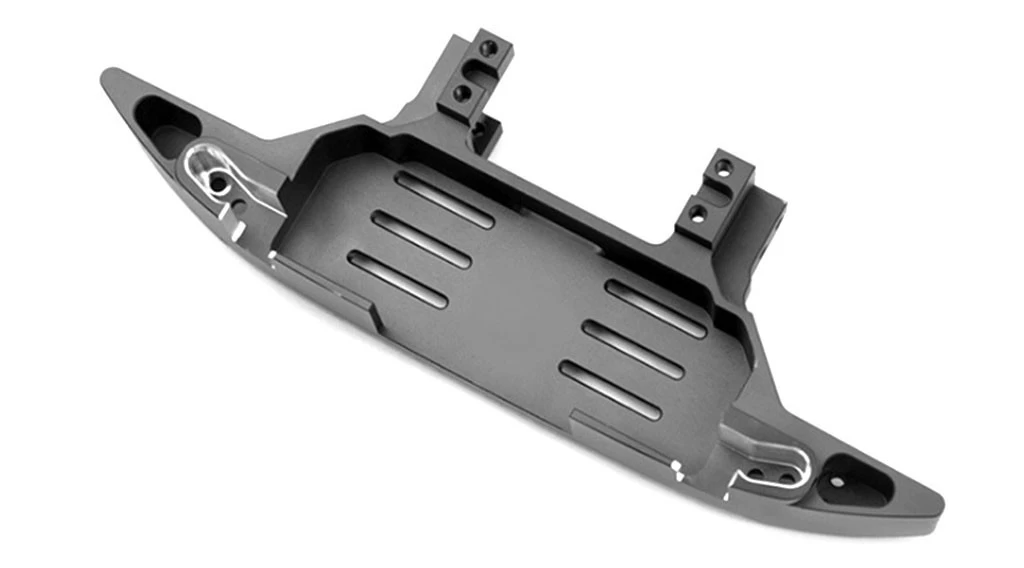

Zinc alloy die casting

First, strength

As far as the market is concerned, the competition of zinc alloy die casting factory is fierce, and the strong enterprises have great advantages in the competition. The strength can be queried in terms of enterprise planning, equipment quantity, skill strength, and personnel allocation.

Ii. Quality assurance

Product quality is the lifeblood of an enterprise. In order to distinguish the quality, we can see whether the appearance of zinc alloy die casting is pitted, burr, deformation, water marks and other quality problems

Third, punctual delivery date

It's time for the fast fish to eat the slow fish. If we don't seize the opportunity in time, the company will suffer serious losses. In this regard, the assumption that the zinc alloy die casting plant cannot make delivery on time indicates that the credit of the enterprise is not good enough and the adaptability of the die casting technicians to deal with the problems in the production process is poor.

Fourth, the service is in place

Service also played a very important role in our later development. In addition to some services from mold design to shipment, there is a very important point, is the mold maintenance service. Assuming this is in place, later collaboration can result in significant savings in production costs for customers.