Discussion on oxygen injection die casting

Oxygenated die casting is divided into: oxygenated die casting and directional suction oxygenated die casting

(1) Oxygenated die casting

When analyzing bubbles in aluminum alloy die castings, it is found that 90% of the gas is nitrogen, while 80% of the air should be nitrogen and the remaining 20% oxygen. This shows that part of the oxygen in the bubble reacts with the aluminum liquid as follows:

4AL+3O2=2AL2O3

According to this fact, a new process of oxygenated die casting was developed.

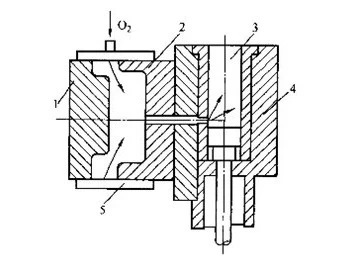

Add oxygen die-casting is before the aluminum liquid metal mold filling, with oxygen filling pressure chamber and cavity, to replace the air or other gas, when the aluminium metal liquid filling, on the one hand, through the vent groove eduction oxygen, on the other hand spray aluminum gold Belong to liquid oxygen react with no discharge and produce A1203 particle, scattered inside the die casting, Thus eliminating the pores formed inside the die cast when no oxygen is added. This kind of A1203 particle particle is fine, about l micron below, its mass (weight) is 0.1% to 0.2% of the total mass (weight) of the pressure casting, does not affect the mechanical properties, and can make the die casting heat treatment. Oxygenated die casting is only suitable for aluminum alloy die casting.

Oxygenated die casting has the following characteristics:

① Eliminate or reduce porosity, improve the quality of die casting. The strength of the aluminum alloy after oxygenation can be increased by 10% and the elongation is increased by 1.5 to 2 times, because there is no porosity in the die casting. Mei can be heat treated, after heat treatment, the strength can be increased by 30%, the yield limit increased by 100%, the impact toughness has also been significantly improved.

(2) The die casting can work in the environment of 200 to 300℃ and can be welded. Compared with vacuum die casting, the structure is simple, the operation is convenient and the investment is less.