Die casting surface temperature will also affect the quality of die castings

Does the surface temperature of the die-casting mold also affect the quality of the die-casting parts? The xy-global engineer will explain to you why the relationship between the surface temperature of die-casting mold and the quality of die-casting parts.

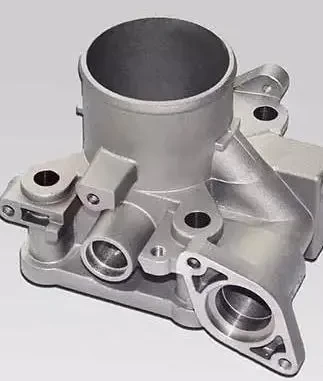

The harsh processing conditions of aluminum alloy die-casting molds require high mold stability. There are hidden dangers in mold design and manufacturing. There will be no leakage through continuous manufacturing processes. Die-casting molds need to be produced. Mold quality stability inspection. Aluminum die-casting molds can be used to ensure that the working conditions of aluminum alloy die-casting molds are relatively strict, the mold stability requirements are high, and the hidden dangers in mold design and manufacturing are not enough to leak in the continuous manufacturing process. Test the quality stability of die-casting molds, die-casting mold wear, erosion, corrosion and thermal fatigue, burr formation, washing, deformation, casting spalling, cracks, fixation, cracking. It cannot be repaired after problems, scratches, roughness or size misalignment.

The mold itself has its normal life. The surface temperature of the die-casting mold is very important for high-quality die-casting parts. If the mold temperature is uneven or inappropriate, the casting size becomes unstable, the casting process is deformed, and cold marks, grooves, fixing types, surface depressions and other defects appear during the manufacturing process. Among them, cold holes and shrink holes are most susceptible to the surface temperature of the die-casting mold, so let's see how to solve them.

First change the mold temperature. It is ejected from the mold, and the type temperature is lowered. Cold mode: how to increase mold temperature

1. Increase the temperature of molten metal

2. Increase the alloy composition

3. Add a vacuum device.

The surface temperature of the die-casting mold is calm, not too hot, not too cold, and it is necessary to rely on a professional mold master to adjust the temperature.

XY-Global is an international manufacturer that specialize in high precision CNC Machining and aluminum and zinc die casting products.Quality and solution support are the core of our service concept,which has been leading us to support lots of our customers in the 3D printer,medical device,Telecommunication,Coffee machine and Electrical appliance fields...

We produce in shenzhen,china and also have sales offices in the united and lsrael with customers all over the world.