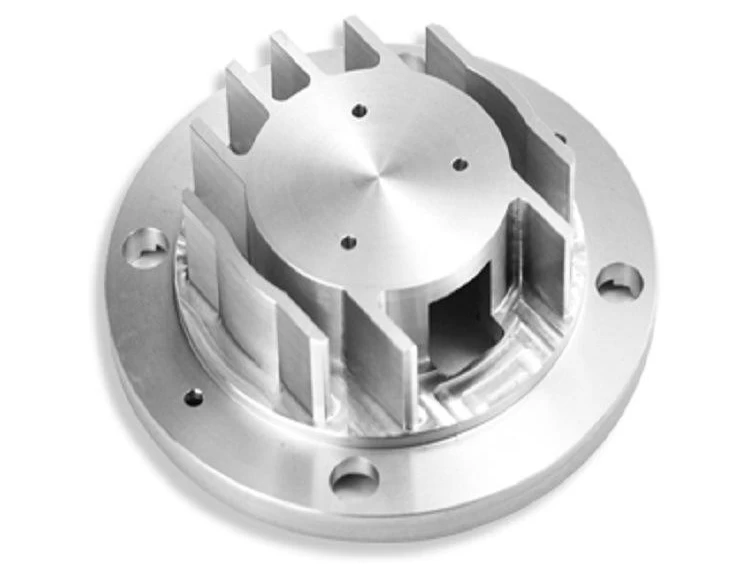

aluminum alloy cnc aluminum products processing

In recent years, with the development of science and technology and the progress of society, people's demand for product diversity has become stronger and stronger. Therefore, the better the processing technology of aluminum alloy products, the more popular it will be, the greater the market demand and the higher the profit. CNC processing is one of the best processing methods for aluminum alloy shell products. In order to meet people's needs for the diversity and high quality of aluminum alloy shell products, processing skills must be summarized in the processing process. Based on years of CNC machining experience, xy-global summarized the machining skills that should be paid attention to in the machining of aluminum alloy shells.

The requirement of CNC machining skills is that the control system can logically process the program specified by the control code or other symbolic instructions and decode it by the computer so that the machine tool can move and process parts. The blank is processed into semi-finished products through tool cutting.

CNC cutting is cutting. For precision machining of aluminum alloys, a more reasonable processing method is also a common processing method. It uses end mills with multi-directional cutting functions, spiral cutting interpolation and contour cutting interpolation. It uses some tools to perform a small number of holes. Processing.

In the CNC machining process of aluminum alloy shell, it is necessary to master the machining process and painting skills.

Choose a reasonable amount of cutting, the staff will choose the cutting speed to be used according to the material to be processed, hardness, cutting state, material type, cutting depth, etc. These conditions are necessary to effectively reduce machine wear. Choose the right tool. Generally speaking, when roughing, it is best to choose a tool with high strength and durability to better meet the requirements of roughing.

As a modern manufacturer of precision mechanical parts, xy-global takes die-casting and CNC processing as its core processes, has physical factories, testing equipment, and integrates supporting manufacturing resources such as rapid prototyping, molds, and post-processing to provide customers with rapid proofing, Small and medium-sized batch production and trial assembly, truly a one-stop service that saves effort and effort; the company has Taiwan imported computer gongs, milling machines, lathes, grinders and other precision machining equipment, as well as a technical team with non-standard production experience. Experience.