How to reduce the cost of mold manufacturing is what each supplier needs to consider

diecastingpartsupplier

www.diecastingpartsupplier.com

2017-05-11 21:36:22

According to the die casting mould supplier china. A substantial good thing about while using the injection mold technique is the opportunity to use several kinds of plastic at the same time. By co-injection the mold material you are able to make use of the preferred kind of plastic which is completely customized and gives the preferred strength and texture.

The automated means of injection mold means it's very cost-effective and mainly operates using robotics and machines. The project is well supervised by one controller, which assists to cut back on overheads and manufacturing costs. Also, the automated nature in the production means the various are produced into a very accurate standard around the first attempt that will reduce plenty of waste materials. Our prime accuracy level is achieved with the aid of the most recent computer aided manufacturing (CAM) and cad (CAD) technologies. After the part is released through the injection mold it provides a high-quality finish and appears much like the finished article without any further work required.

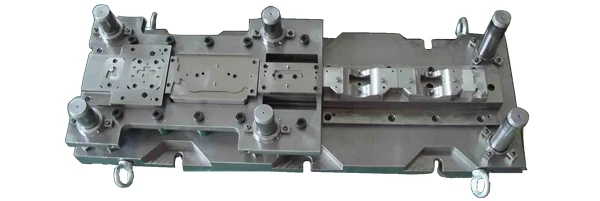

oem plastic mold company, cheap mold maker china, die casting mould supplier china