What is Vacuum casting

What is Vacuum casting

Vacuum casting is the process of using a ventilated mold. The molten metal flows into the mold by air pressure and then removes the air to form a vacuum. This casting method is mainly used for small parts with fine details or jewelry.

Vacuum modeling

Vacuum modeling is a physical modeling method, which combines vacuum technology with sand casting, relying on plastic film sand mold cavity surface and the back surface sealed, with the vacuum pump pumping negative pressure, resulting in sand mold inside and outside Pressure to mold sand tightening molding, by placing the sand heart, mold, casting, waiting for casting solidification, the lifting of negative pressure or stop pumping, mold sand will then collapsed and get cast. According to the current application of the field can be divided into vacuum seal modeling (V method) and real vacuum casting (FV method). Its advantages are:

(1) moderate degree of vacuum, mold cavity compactness, casting quality is also high.

(2) Vacuum casting with the mold simulation analysis of the computer can predict the generation of casting defects, for the design of the design program, can significantly save time and improve production efficiency.

Vacuum casting

Vacuum casting can be divided into vacuum suction, vacuum low pressure casting, vacuum pressure casting.

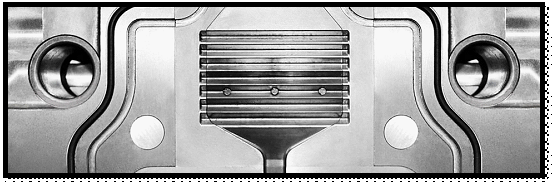

1, Vacuum suction

Figure 1 Schematic diagram of a vacuum suction As shown in Figure 1, the mold placed in a closed container, the mold out of the air, so that the mold caused a certain negative pressure, resulting in molten metal into the mold cavity. When the casting of the inner runner solidification, remove the negative pressure, so that the runner without solidification of molten metal back into the pool. The advantage is to improve the filling capacity of the alloy liquid, the minimum wall thickness of cast castings up to O. 2mm, while casting area of 300mm2, while reducing the pores, slag and other defects. Applicable to the production of thin and fine small precision castings, cast steel (including stainless steel) pieces are particularly suitable. Its advantages are:

(1) vacuum suction is conducive to the removal of gas in the mold, inhibit turbulence and the generation of gas, to overcome the shortcomings of low pressure casting and differential casting, so that the filling capacity of metal liquid significantly improved.

(2) due to vacuum suction, the filling capacity of the increase, the molten metal casting temperature can be lower than the gravity casting 20 ~ 30 ℃.

(3) Castable wall thickness difference between the large, thin-walled, high quality requirements of the casting.

(4) by selecting the appropriate degree of vacuum change rate, control the metal liquid into the mold cavity speed, you can get a smooth filling effect.

2, Vacuum low pressure casting

Vacuum low pressure casting method is in the process of pressurization filling mold vacuum, filling the pressure after the casting at a constant pressure crystallization under the solidification, casting fully filled, so the casting organization is dense, mechanical properties. This method is used for Al, Mg alloy casting precision casting. Its advantages are as follows:

(1) the presence of vacuum negative pressure, can make the mold sand is compact, increasing the strength of the mold.

(2) moderate increase in vacuum, so that filling time is shorter, not only filling speed and smooth.

(3) Vacuum low pressure casting can accelerate the flow of aluminum alloy at low temperature, to avoid high temperature casting caused by the phenomenon of aluminum alloy suction, and increase the casting pinhole defects.

(4) casting good formability, is conducive to the formation of clear contours, smooth surface castings and large thin-walled castings.

(5) casting organization is dense, high mechanical properties.

(6) under normal circumstances do not need riser, so that the metal liquid yield greatly improved, usually up to 90%.

(7) good working environment, simple equipment, help mechanization and automation.

3, Vacuum pressure casting

Vacuum differential pressure casting, mainly is the resistance of the furnace and mold all sealed, in the seal through the pressure of the larger pressure such as 500kPa into the compressed air, then the mold and the internal pressure of the crucible equal, the metal will not rise , And then in the metal surface to add 50kPa pressure, the metal liquid will rise filling mold cavity. Especially for the production of complex thin-walled castings, but the equipment is relatively large, operational trouble, only special requirements when applied. Its advantages are as follows:

(1) Compared with the traditional gravity casting and vacuum suction casting, vacuum differential pressure casting in 1mm thick sheet on the sample reflects the good filling capacity.

(2) casting has a more compact crystalline structure and mechanical properties, casting strength performance, than the vacuum casting and gravity casting increased by about 20% to 25%, elongation is increased by about 50%.

(3) vacuum die can effectively reduce the stamping of the stamping of the casting, improve the density of castings more than 1%.

XY-Global provide customized service for mechanical parts, undertaking OEM and ODM order. Here is our website : www.xy-global.com .